床垫包装膜与床垫压缩机的配合使用为床垫制造商提供了极大的便利。通过压缩床垫并使用高质量包装膜,可以降低运输成本并提高床垫的储存效率。

Combination of mattress packaging films with mattress compression machines offers great convenience to mattress manufacturers. By compressing the mattress and using high-quality packaging films, transportation costs can be reduced and mattress storage efficiency improved.

床垫包装膜的性能要求

Performance Requirements for Mattress Packaging Films

床垫包装膜需要具备良好的拉伸性、抗撕裂性和耐磨性,确保在床垫压缩后的运输过程中,包装膜不易破损。

Mattress packaging films need to have good stretchability, tear resistance, and wear resistance to ensure that the packaging film does not easily tear during the mattress compression and transportation process.

床垫压缩机的作用

Role of Mattress Compression Machines

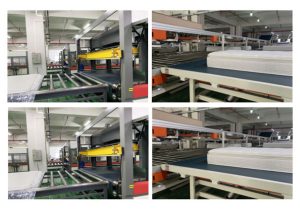

床垫压缩机通过对床垫进行压缩,减少床垫的体积,为包装膜提供更紧凑的包装空间。

Mattress compression machines compress the mattress to reduce its volume, providing a more compact space for the packaging film.

包装膜与床垫压缩机的协同作用

Synergistic Effect of Packaging Films and Mattress Compression Machines

床垫包装膜与床垫压缩机的协同工作,不仅提升了包装效率,还确保了床垫在运输过程中的安全性。

The cooperation between mattress packaging films and mattress compression machines not only improves packaging efficiency but also ensures the safety of the mattress during transportation.